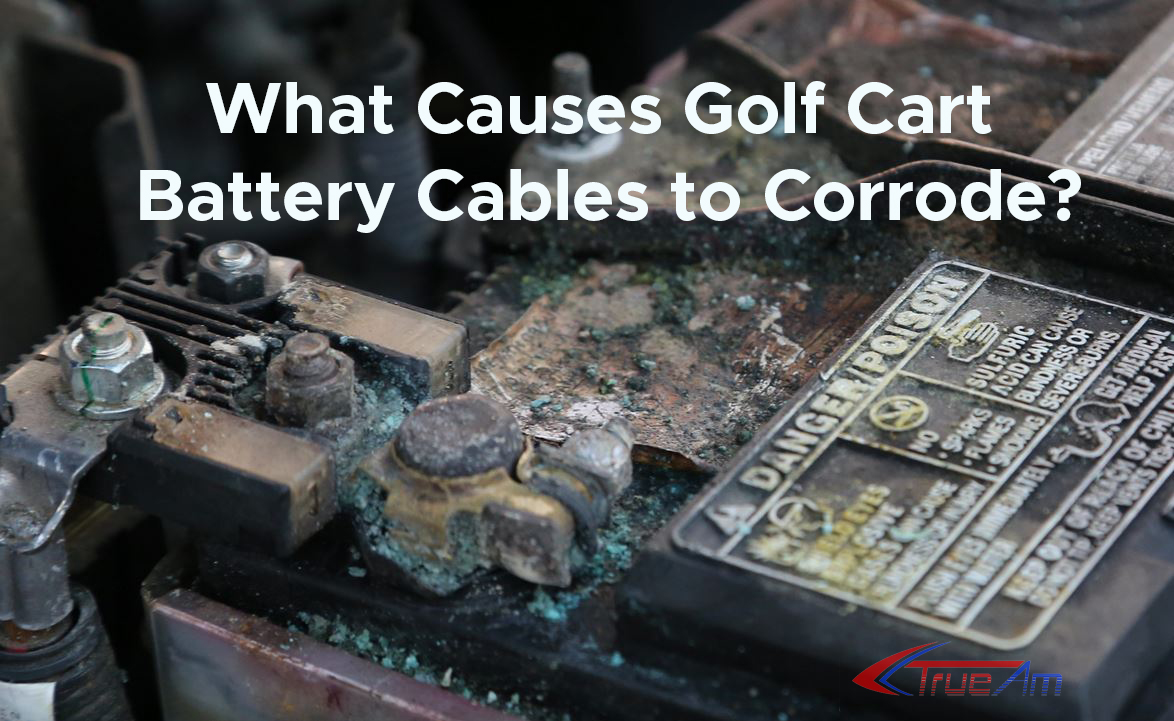

For a variety of reasons, golf cart battery cables can corrode. Corrosion on battery cables can cause poor electrical connections, decreased performance, and even system damage.

The following are some of the most common causes of corrosion on golf cart battery cables:

Chemical Reactions:

Because battery terminals are typically made of lead or lead alloy, the sulfuric acid in the battery’s electrolyte can react with them, resulting in the formation of lead sulfate. This reaction can cause corrosion on the terminals and the cables that connect to them.

Moisture and Humidity:

Moisture and high humidity can contribute to battery cable corrosion. If the golf cart is stored or operated in a damp environment, the corrosion process will be accelerated.

Acid Exposure:

Accidental spills or leaks of battery acid onto the cables can result in rapid corrosion. It is critical to exercise caution when handling batteries and to clean up any acid spills as soon as possible.

Age and Wear:

The battery cables can become worn over time, and the insulation can degrade. As the insulation deteriorates, the exposed metal may become more corrosive.

Loose or poorly connected cables:

When battery cables are not securely connected to the battery terminals, gaps form, allowing moisture to enter and accelerate corrosion.

Inadequate Maintenance:

Failure to inspect and clean battery cables on a regular basis can result in a buildup of dirt, grime, and corrosive substances on the cables, increasing the likelihood of corrosion.

Chemical contaminants in the environment:

Chemical condition of the air such as salt (which is common in coastal areas) and industrial pollutants, can exacerbate corrosion.

To prevent or reduce corrosion on golf cart battery cables, it is critical to:

- Inspect the golf cart battery cables on a regular basis for signs of corrosion or damage.

- Keep the battery area clean and clear of debris that could trap moisture.

- Apply a protective coating to the battery terminals and cable connections, such as battery terminal grease or a corrosion inhibitor.

- Make sure the cable connections are snug and secure.

- When servicing the batteries, avoid overfilling or spilling the battery acid.

- If possible, keep the golf cart in a dry and sheltered location.

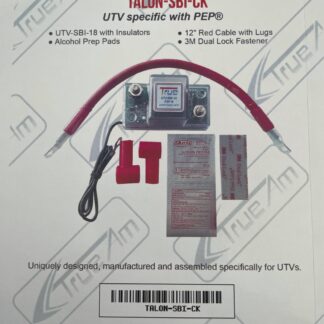

- Use TrueAm® 4 gauge battery cables – it is sealed, water-proof and heat shrunken cable